TRADITIONAL ANIMATION

TOOLS

1. Animation Disc

2. Pencil

3. Peg bar

4. Eraser

EQUIPMENT

1. Ergonomic computer tables and chairs

Cintiq

Pen tablet

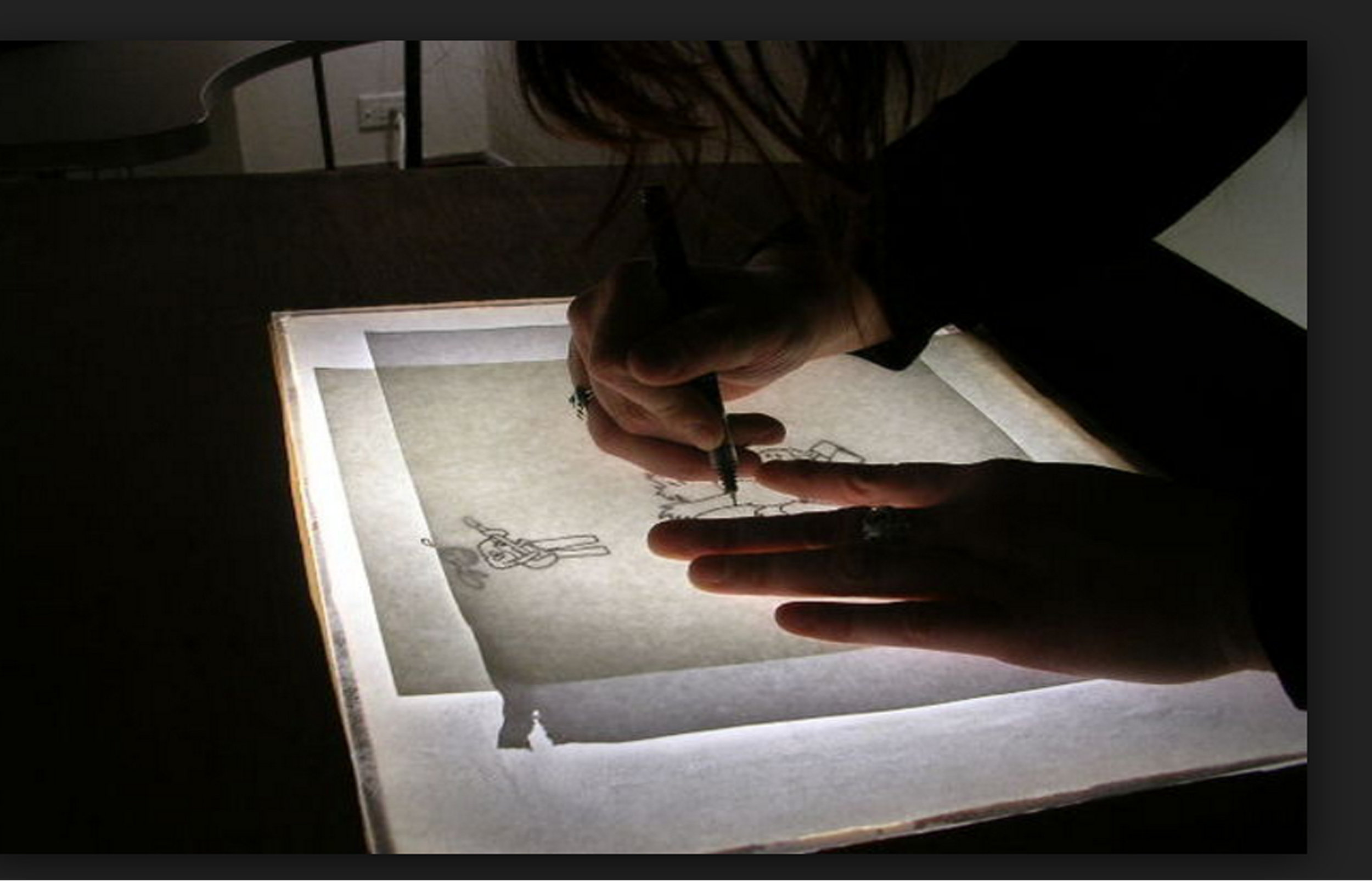

2. Light box

Light table

Animation light table

3. Printer

MATERIAL

1. Animation paper

2. Bull clip

3. Learning materials/ guide

animation book

4. Printable storyboard

5. Practice materials

WORK AREA

Floor Area

Maintenance is an excellent means of improving the performance and condition of equipment and facilities. An effective maintenance program

identified problems long before any equipment or facility breaks down or

deteriorate. A good maintenance system presents the early discovery of

problems, thus providing plenty of lead time for effective maintenance planning. The trainer has to value the importance of maintaining the training facilities, equipment and tools he is using or under his care if he values the presence and availability of these resources for effective trainin and learning processes.

The Growth of Interest in Maintenance

The factors contributing to the rapidly growing interest in maintenance are:

1. Technological development

This trend leads to a more mechanized and automated

equipment, resulting in great productive potential which must be

kept working. This means that training facilities are becoming

more complicated and required more advanced maintenance.

2. Increasingly expensive raw materials

Finite raw materials, in combination with a growing population and increasing assumption, inevitably result in higher raw material prices. Unavoidably, the costs of all by-products must rise. It is therefore often more profitable to maintain existing equipment than purchase new ones.

3. Greater complication

A complicated facility of piece of equipment includes many

components, any or all of which can constitute possible sources of

trouble. Although the operational reliability of each individual

component may be very high, it is necessary to multiply reliability

factor of all components that are dependent on each other in a system in order to arrive at the total system reliability.

4. Increased fixed costs

Capital costs constitute a considerable part of the total costs

of training and must be covered by the added value created. If

training stops as a result of inadequate maintenance, capital costs

(depreciation) must still be paid, so that the standstill results in a

net loss. Still, the salaries and overhead expenses must be paid

while training is stopped.

5. Reduce delayed activities and eradicate uncompleted work

Many work processes depend on an uninterrupted flow of

activities to produce desired result. If an activity is delayed, the

entire work stops. If all the facilities and equipment are reliable

working well, work delay can be reduced.

6. Environmental concern

The growing quantity of electronic wastes (monitors, laptops,

cellular phones, other electronic gadgets and its substances), the

increasing use of chemicals such as cleaning agents, paints, fuel

and its derivatives, the by-products created from its use, and its

disposal, pose danger to the environment and all living things.

Mass awareness on waste management brings the relevance of

conserving the natural resources and the products (machines, tools)

thru proper maintenance to lengthen its useful life.

Training Equipment and Supplies

Training equipment is usually placed in the practical work area or the trainee resource area. The sizes and uses of equipment vary in the different training qualifications and generally classified into five (5):

1. Large items of equipment – motor vehicles, industrial sewing machines

2. Small items of equipment – video/tape recorder, espresso machine

3. Simple equipment – electric fan, floor polisher

4. Complex equipment – plasma cutting

machine, simulator (automotive)

5. Equipment with significant health and

safety implications – duplicator machine

Why Maintain?

General Objective:

• To keep the optimum condition of physical facilities at acceptable levels and minimum cost to satisfy the expected of programs, services and activities at acceptable and minimum costs

Specific Objectives:

• To extend the useful life of physical

facilities

• To assure the operational readiness of

installed equipment and maximum

possible return on investments

• To properly discard hazardous wastes

• To ensure the safety of personnel using

the facilities, physical properties and the environment

What can we gain from maintaining our facilities ?

• Ensured SAFE environment

• Improved MORALE of human resources

• Reduced operational COST

• Increased PRODUCTION

• Prolonged LIFE of facilities

• Prompt DELIVERY of services/product

• WASTE/Garbage reduction

Who are involved?

• Who will manage the activities?

• Who will monitor and evaluate the operations?

• Who will prepare the maintenance schedule?

• Who will implement the program?

• Who will keep the records?

• Who will conduct inspection?

• Who will certify and accept the work?

• Who will prepare the report?

What, Where, When?

• What routine actions must be done to keep the device on working order?

• Where is the maintenance activity to be carried out?

• When do you perform the maintenance activities?

How to maintain?

The question on how do we

implement the maintenance program

will center on the 5Ms as follows:

• Manpower

• Money (Financial Resources)

• Methods and System

• Machines (Facilities)

• Materials and Supplies

A maintenance program is a comprehensive list of maintenance and its incidents. This would include all maintenance activities to be undertaken, manpower needed, maintenance methods to be used, all the materials and supplies needed and cost involved in the maintenance .

A maintenance schedule is a list allocating specific maintenance of an area, including equipment and tools to a specific period.

The maintenance schedule is just a part of the maintenance program. A maintenance checklist is a list of maintenance tasks (preventive or predictive) typically derived through some form of analysis, generated automatically as work orders at a predetermined frequency.

To perform the maintenance of specific equipment, a maintenance

schedule is drawn. Again, the best source of the list of the maintenance

activitie of equipment is its manufacturers/user’s manual. In the absence

of it, the plan can be derived from the known maintenance methods of the

equipment and in accordance with the organization’s policy and procedures.